Special moulds

Precast concrete elements can be used in variety of applications. We supply special moulds for wind turbines, straight or curved terraces for sports stadiums and arenas and concrete road barriers (New Jersey elements) as well as pre-stressed poles for vineyards, for orchards, for anti-hail nets, for greenhouses, for fences and purlins with different dimensions and thicknesses. Our many decades of experience and our commitment to working with infrastructure projects all over the world has put us in the forefront of design and manufacture of innovative moulds for shaped precast concrete elements for various applications, contributing effectively to our customers' success.

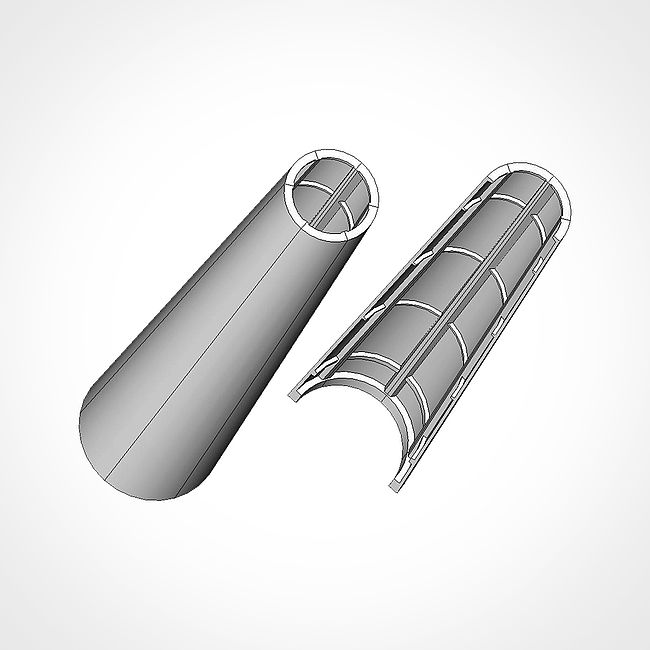

Elements for wind turbines

Our innovative solutions meet our customers' needs. There is an increasing demand for wind turbines and so we design specific moulds for wind turbine towers according to our customers' engineering specifications, such as solutions with a variable conical cross-section. The post-tensioning technology is used to combine the elements.

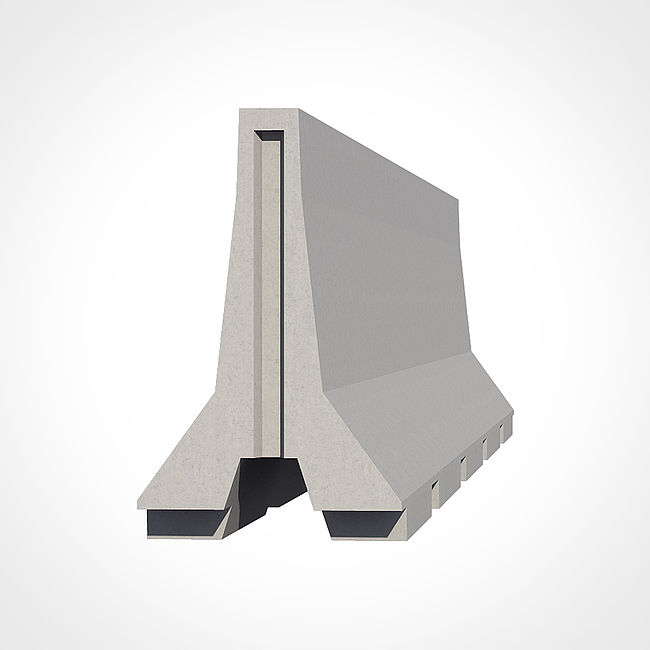

Concrete road barriers / New Jersey elements

A high degree of flexibility in the construction of moulds results in a high, flexible production performance in the mass-produced products, such as New Jersey elements.

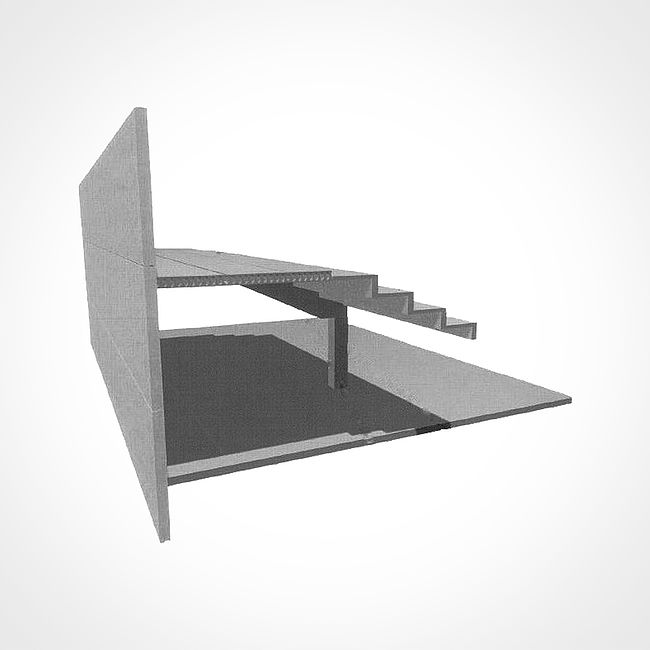

Sports stadiums

The highest manufacturing precision of our moulds allows the combination of different precast element geometries for sports stadiums and arenas. Curved stadium terraces with variable radii of curvature and variable heights are realized according to customer requirements. Pre-stressed variants allow larger spans for these applications.

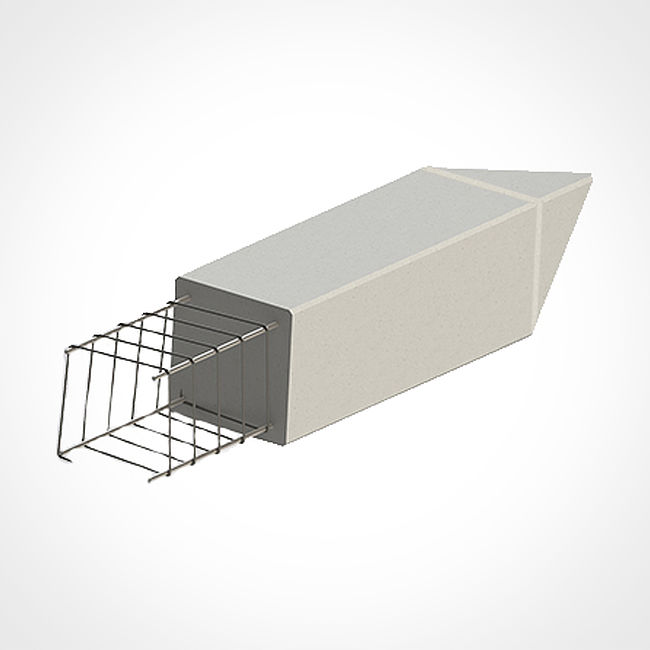

Pre-stressed poles for orchards and vineyards

The long beds are the ideal solution for an efficient mass-production of pre-stressed poles. A remarkable quality improvement of the concrete elements mechanical features regarding durability as well as to a significant dimensions and weight reduction is guaranteed by the pre-stressing technology with hydraulic tensioning and de-tensioning system.

In addition to the long casting beds the lines include also other components such as distributing screeds, lifting and cutting units, smoothing/cleaning/oiling machines, dereeling devices for coils and electric tow- winches.

Upon request we can include in the scope of supply also batching plants, concrete distribution systems and heating systems in container.The lines can be equipped also with vibrators for concrete compacting and heating system for concrete curing.

SPEEDCAST 5.0

System of concrete distribution versatile and efficient

SPEEDCAST is a mobile operating machine on wheels for the transport and distribution of concrete and cement agglomerates on moulds suitable to receive concrete (S2-S3-S4 and beyond up to SCC class).

It has been designed to meet the needs of a particular field of concrete distribution systems inside precast concrete factories.

- maximum versatility

- excellent mobility

- extreme semplicity of use

- great performance and total compliance with regulations

- easy to transport

Professional start-up service

The spearhead of our Customer service is the professional consulting and training about the use of the equipment and about the production process, to achieve a first-class quality product.

Automation & Innovation

Versatility

Turn-key solutions