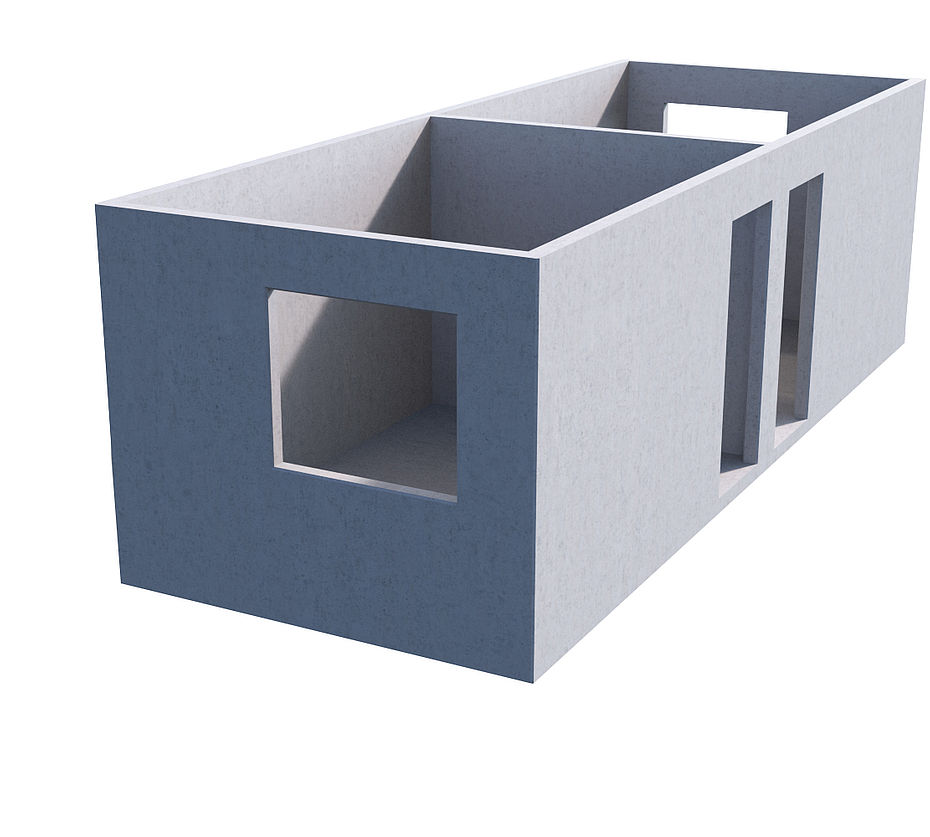

Our range of moulds for spatial precast concrete elements encompasses a wealth of solutions with different degrees of automation. The moulds are used for the production of 3D elements with lateral walls in combination with roof or floor elements. The inner core of the mould can be configured conically or with hydraulic or mechanical shrinking. The moulds can be supplied with shutters for window and door apertures or other partial subdivisions. They are used for prefabricated massive residential modules, transformer stations, water tanks, garages, lift shafts and ducts. They can on request be configured with various heating systems to accelerate the curing process and with vibrators for compaction of the freshly poured concrete and to improve the surface quality. The moulds can be filled from above or through the side by a pump system.

Fast and precise construction of components

Modular construction with precast concrete elements in various sizes (height, width, depth).

Production of 3-D precast concrete elements with integral hydraulic or electrical equipment and with heating systems. Particularly suitable for bathroom units or residential modules, with higher productivity.

“F” series: 3-D elements with flooring plates

Areas of use for the F series - precast concrete elements

- residential modules

- transformer stations

- water tanks

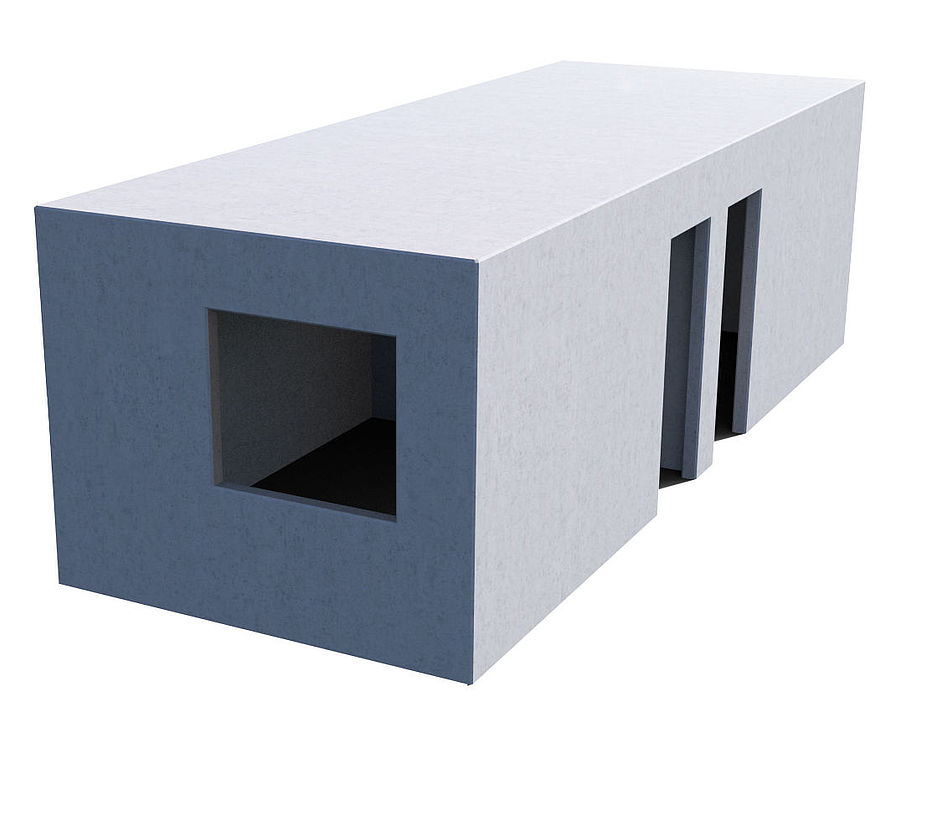

"R" series: 3-D element with top cover

(copy 2)

Areas of use for the R series - precast concrete elements

- residential modules

- bathroom units

- garages

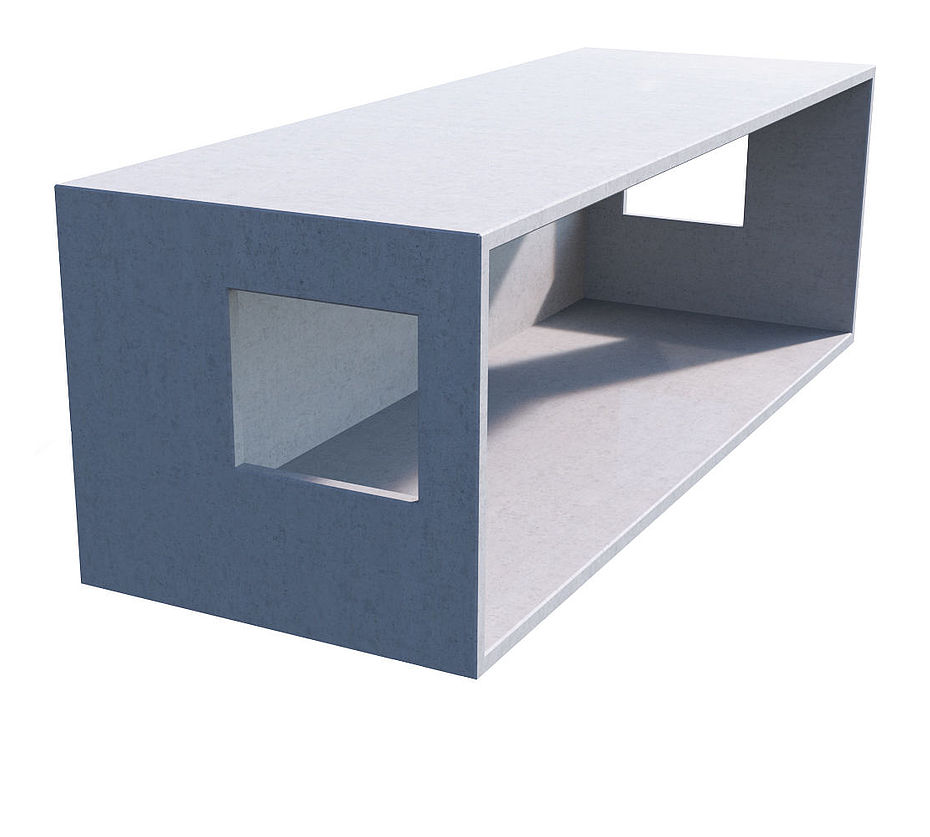

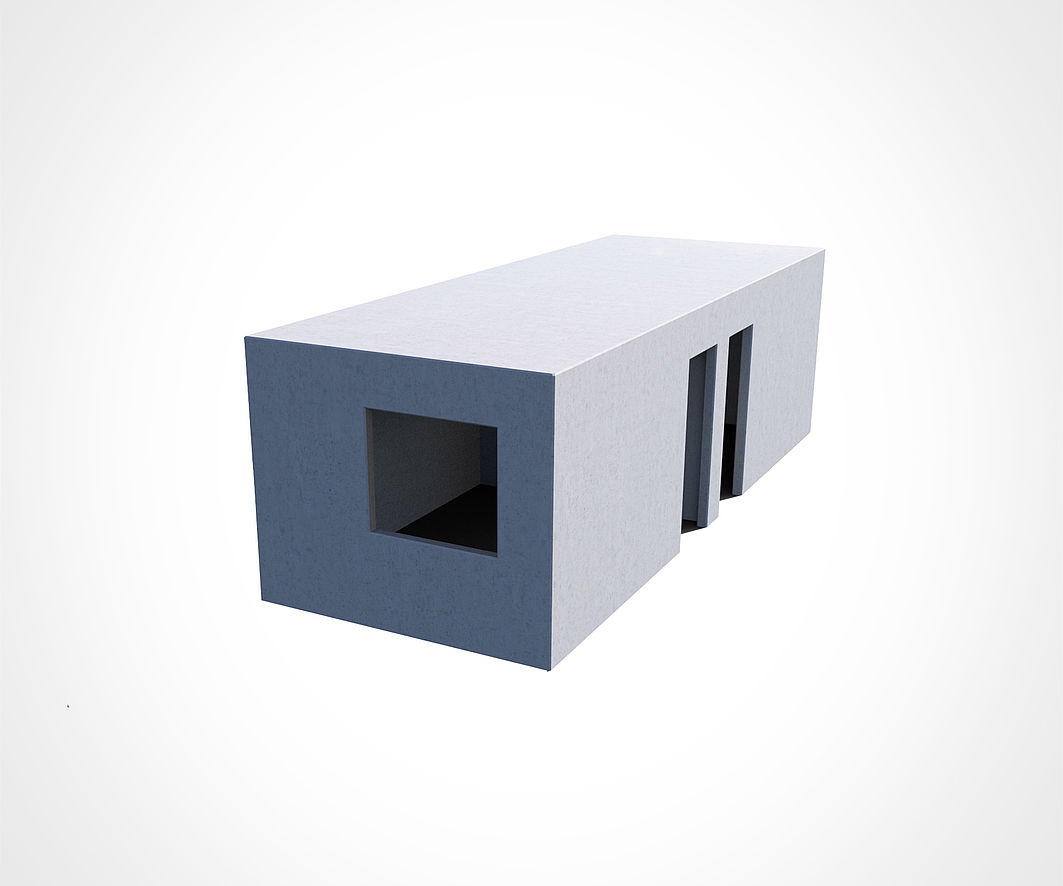

“K” series: Vertical production technology cube modules

Areas of use for the K series - precast concrete elements

- residential modules

- garages

The surrounding sides of the cube modules (ceiling, floor and lateral walls) are manufactured in only one casting for maximum solidity and stability.

Optimizing the investment

Innovative construction method

Optimizing the production site